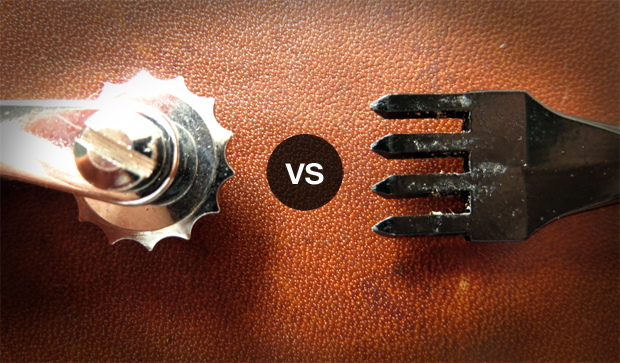

As the old saying goes there is more than one way to skin a cat. This applies even to the seemingly simple task of marking your stitching holes. There is always a lot of debate over this topic and there is no right or wrong answer. Today we are going to take some time and explain the good and bad of each method.

The Stitching Wheel

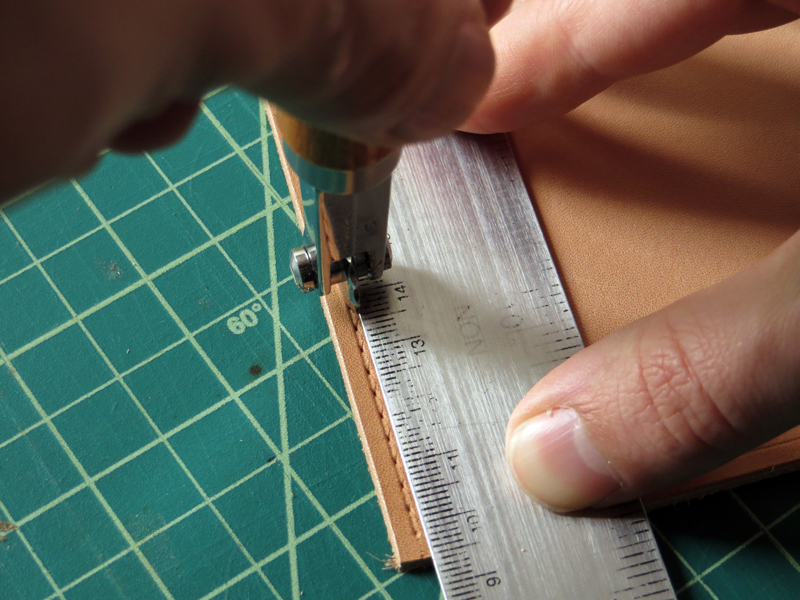

The stitching wheel is usually one of the first tools a new leathercrafter will purchase when starting out. They come in a variety of different models and most have an interchangeable wheel system for adjusting to your desired stitch length. Lets go over some of the advantages of using a stitching wheel to mark your holes.

Stitching Wheel Advantages

- It’s Quick – After marking your stitching groove the stitching wheel allows you to mark holes very quickly. The more accurate you become using the wheel the more rapidly you can complete that step of your projects. This is especially true for projects with a lot of short, straight sections.

- Handling Curves – A major feather in the stitching wheel’s cap is the ability to handle curves. Diamond chisels are forged in straight lines and aren’t as agile in situations where there are a lot of curves. The freehand motion of the stitching wheel allows you to mark holes flawlessly in curvy or tight edge situations.

- Custom Awl Holes – The stitching wheel only marks your leather so after that you are responsible for punching the actual hole. The beneficial part about this is you choose the size of your awl, the size of your awl hole, and the angle at which you want your stitches to lay (stacked stitches). For example if you were stitching a watchband usually that requires very delicate stitching with a thin thread. You can now control the depth of the hole you are punching and make sure to keep them small and neat.

- Cheap Investment – As mentioned earlier most stitching wheels aimed at novice leathercrafters come with an interchangeable set of wheels. For the initial investment you get a few different options to try out with your stitch length. Diamond chisels come in a few sizes but your cost will quickly add up collecting each size individually.

Stitching Wheel Disadvantages

- Custom Awl Holes! – Punching holes in leather with an awl is a basic leathercrafting skill but takes a long time to produce clean lines. Its very easy to punch a hole inaccurately and make a mess of your work.

- Long, Straight Lines – The stitching wheel is great on curves and short sections but can become troublesome on long straight lines. It only takes a second to run out of your groove and leave permanent marks on your project. A remedy for this problem is to use a ruler to guide your stitching wheel through long sections.

The Diamond Chisel

The stitching wheel isnt the only game in town when it comes to marking holes. The diamond chisel is an awesome tool that can save you a lot of time on a project. While they can produce excellent stitch lines they do have some drawbacks. Lets go over some of the advantages and disadvantages of using diamond chisels to mark your stitching holes.

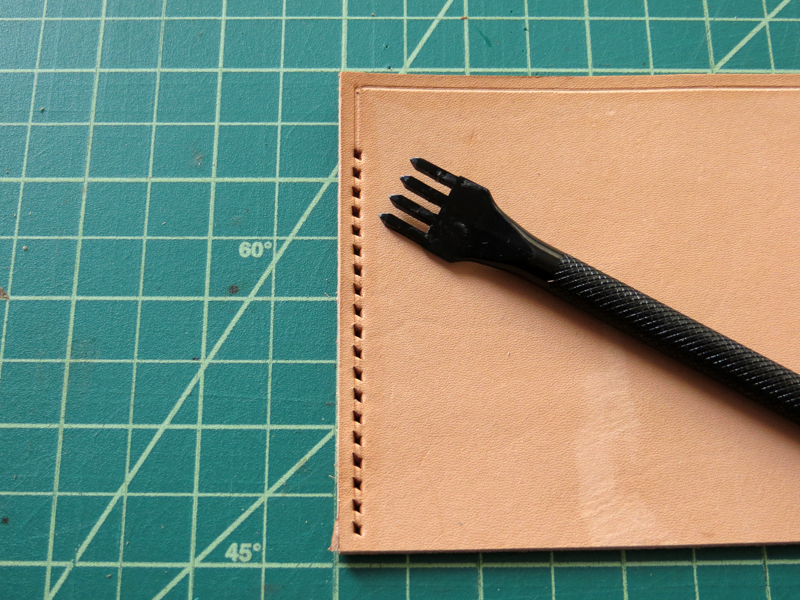

- Straight, Consistent Sized Holes – This the bread and butter of the diamond chisel world. When punching holes by hand with an awl it is very easy to accidentally change your grip angle or punch too deep or too shallow. With a diamond chisel you get very consistent holes because the angle is set in steel. Diamond chisels are worth their weight in gold for long straight lines. Notice how homogenous the holes look in the photo below.

- Punches in Bunches – Diamond chisels come with a variety of different sizes. You can get them in 1, 2, 4, 8 and more teeth per row. This allows you to use a small tooth size for curves and short lines and a larger tooth size for long pieces.

- Time Saver – The fact that you are not only marking but also punching your holes at that moment saves a lot of time. For projects with a lot of hard angles tailoring your project dimensions to the hole spacing of the chisel can increase your productivity even further.

Diamond Chisel Disadvantages

- Curves Can Be Slow – The rigid structure of the chisel doesnt lend well to curves. It is an absolute necessity to have a two-tooth chisel to go around curves. You will blast through straight lines but hit the brakes when it comes to curved sections.

- Can Get Pricey – Diamond chisels come in a variety of sizes and you will need at LEAST two to make the most out of them. A four-tooth and a two-tooth are a bare minimum. However most people opt for more teeth and a single tooth chisel as well. Purchasing all these chisels can burn a hole in your pocket if you’re not careful.

- No Hole Size Control – When it comes to diamond chisel holes its one size fits all. If punching holes on very thin leather you may get away with a slightly smaller hole because you need less force but if you are punching through 3 layers of a wallet you will get the full size. This problem also needs to be addressed in your thread size. If using relatively thick thread you wont have any problems but if you want a thin thread machine-stitched look to your work the larger holes are going to show prominently. For an example see the photo below. The thicker thread fills up the space nicely but as you get thinner it becomes more apparently.

“Hey, What About Pricking Irons?”

Pricking irons are another great tool for marking holes but I opted to leave them out of this comparison (mainly because I dont have one in the shop). They are very similar to diamond chisel with the added benefit of a smaller hole size after punching. While the diamond chisel punches “diamond” shaped holes in your leather the pricking iron punches small diagonal lines that are made to represent the angle your awl should pass through. Traditionally pricking irons were just used to mark the leather much like a stitching wheel. However there are plenty of people who will punch them all the way through the leather.

Conclusion

In conclusion there are obvious benefits and down sides to both methods. The stitching wheel can lay down marks quickly and handle curves with ease. The diamond chisel can make picture perfect lines and homogenous holes time and time again. Are you working on a delicate watchband with machine-width thread? Might want to skip the diamond chisel because the holes would be glaring. Laying down a line of holes on a hand-stitched tote bag? You should probably grab the largest tooth chisel you can find and start hammering away. Consider your materials and final aesthetic and choose wisely!

1 comment

Finally, the explanation I’ve been looking for! Thank you for this, and as a beginner I’m looking forward to more posts like these.

Comments are closed.