Download the FREE SVG or PDF Template below. The SVG is for use in your laser cutter and the PDF is for anyone that wants to print it out. The design is for the card wallet only without the engraving. If you are interested in the exact same engraving style you can find the design here – Retro Angry Robots.

- SVG (Laser Ready File) – Leather Card Wallet (SVG)

- PDF (8.5″ x 11″) – Leather Card Wallet (Letter Size – Print)

- PDF (A4) – Leather Card Wallet (A4 Size – Print)

- Acrylic Template Set – Leather Card Wallet (acrylic)

Usage Note: You are free to use this design to create and even sell the end product. However, you cannot re-distribute this template in any form.

Looking to start selling your handcrafted leather goods and need an e-commerce platform? We recommend you start with what we use here at Makesupply… Shopify!

Inventory of Tools

- 36″ x 24″ Self Healing Cutting Mat

- No.2 X-ACTO Knife

- Wood Slicker

- Table Clamp Stitching Pony

- Aquilim 315 Cement

- Glue Pot

- Plastic Spreaders

- Neatsfoot Oil

- Thread Nippers

- Bone Folder

- Airbrush Masking Tape

- Dummy Credit Cards

- Microfiber Cloth

- Thickness Gauge

- Empty Paint Marker

- Fiebings Pro Dye (Black)

- C.S. Osborne Scratch Awl

- John James Stitching Needles – 002

- Generic Sandpaper – 320 Grit

- Dremel with Sanding Bit

- Ritza Tiger Thread – .6mm (Cigar)

- Tokonole Burnishing Gum

- Seiwa Edge Beveler (#1)

- Electric Edge Creaser

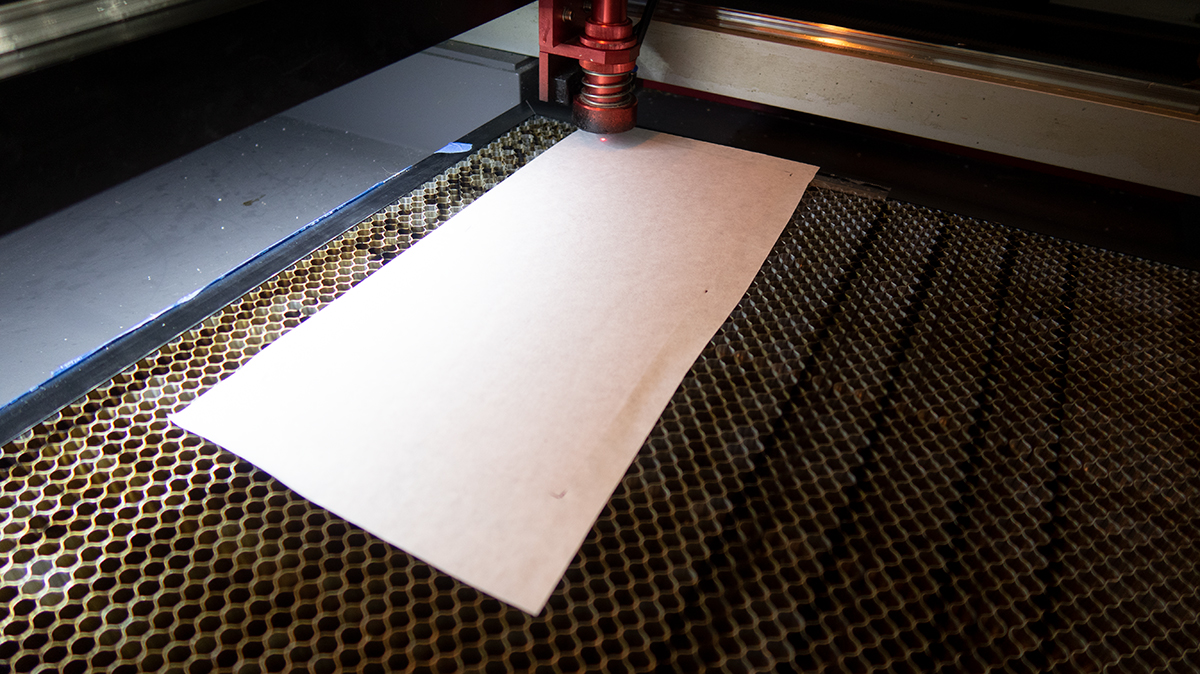

- Boss LS-1630 Laser Cutter

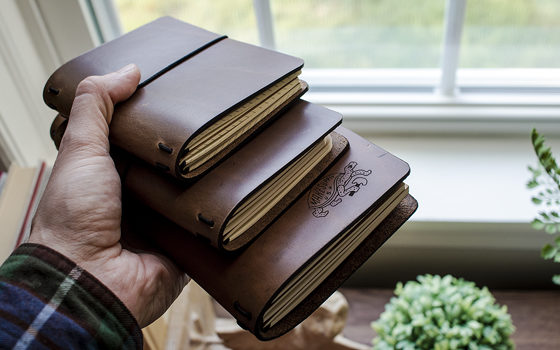

Leather Selection

In this video we used Valdibrana Conceria, Tarano Italian Vachetta Leather – 3.5oz (~1.5mm) thick. This pattern is designed for a leather in that thickness range. Slightly thicker or slightly thinner will probably work but it is optimized for 1.5mm. If you are laser cutting I HIGHLY suggest sticking with a pure vegetable tanned leather.

Instructions / Project Notes

Cutting Panel

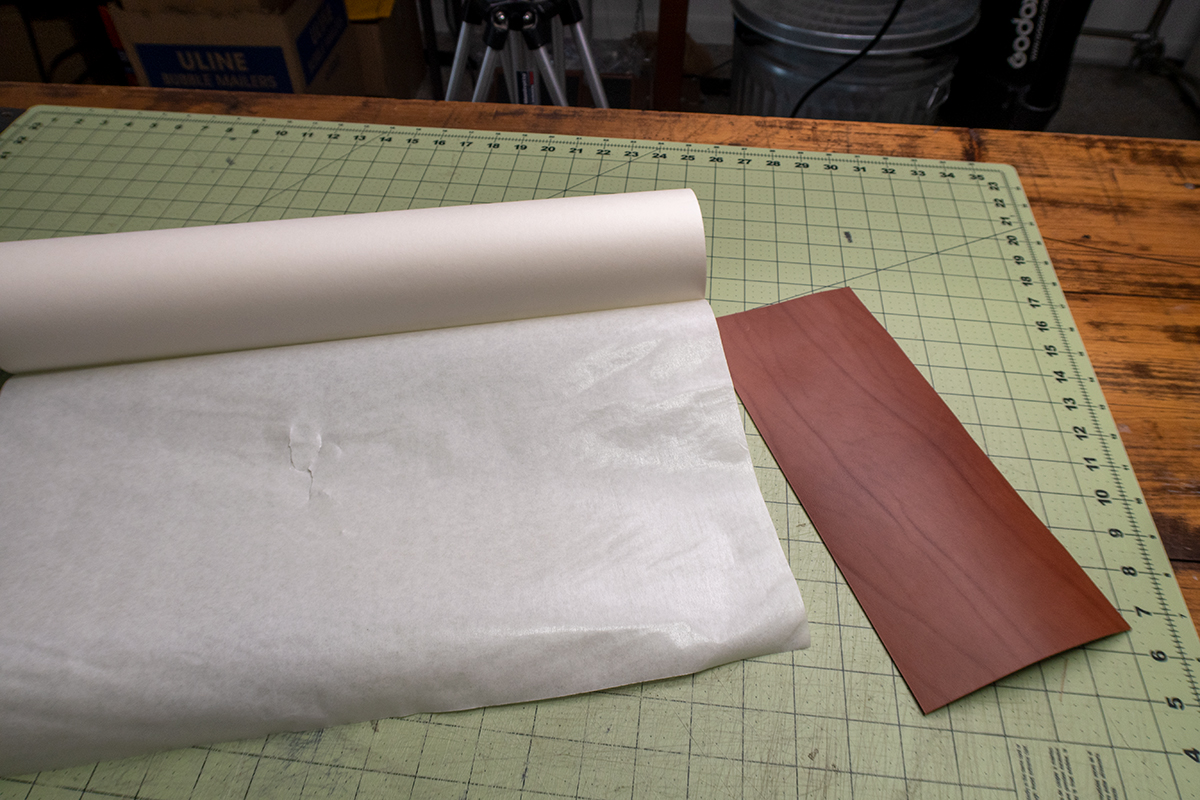

I cut a small panel of leather with a little bit of margin on all sides.

Masking the grain surface

This step isnt necessary but masking the cutting surface with a low-tack masking tape helps keep the surface clean during laser processing. This wide mask is the best Ive found so far, link above if you want to check it out.

Laser Cutting Leather

I am using a 65w laser to cut the pieces. All lasers/materials are different so please do some tests to see what engraving and cutting settings work best for your machine. I overestimated how much power I needed for the engraving and it went a little deeper than I had hoped. Very important to test first!

Laser Burn Clean Up

Next I removed the masking tape and started cleaning the surface. I start by lightly brushing the surface with a dry microfiber cloth to remove the excess soot. Next I use some 100% neatsfoot oil on a microfiber cloth to clean the rest. Dont go overboard with the oil or it will pool in the engraved areas.

The Top Edge

Next I sand, dye and burnish the top edges of the wallet pieces. I am using some Fiebings Pro black dye in an empty paint marker to apply. Highly suggest it! I also run a crease around the edge with my electric edge creaser. This step is completely subjective.

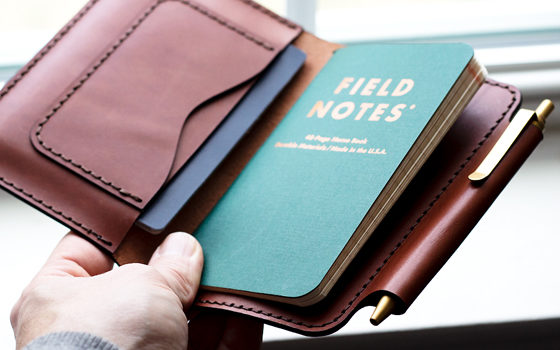

Gluing It Up

First glue the front card slot to the front panel. Next the front panel assembly to the back. I am using a water based adhesive called Aquilim 315 (link above). Use the glue sparingly or it will pool into the cut holes. If that happens use a scratch awl to remove the excess. Once it dries its not a big deal. Gluing the edges properly at this step will allow you to have a nice burnished edge at the end.

Handstitching

For handstitching I am using a .6mm Ritza Tiger Thread. The holes are ~1mm in diameter so there is enough room to size up to a .8mm if you would like thicker thread. I wouldnt do much above .8mm or below .6mm.

Final Edge Finishing

Final step is to sand, bevel, dye, and burnish the body edges. I used a dremel with a sanding bit to remove all of the laser soot and glue spillover. HIGHLY SUGGEST putting on a mask for this step since it will be kicking up all that nasty stuff into the air around you. After sanding the edge should be nice and clean and you can finish as you normally would from there.

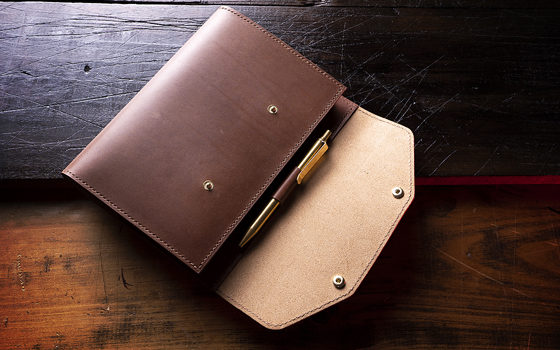

Final Product

Guidelines of Template Usage

We put a lot of time and effort into producing these templates, videos, and blog posts. Please do not distribute the template you have purchased from Makesupply. It’s not cool and hurts our feelings (CRY EMOJI). However, you are free to do whatever you want with the end product you create using the temp